Contact angle goniometry for surface energy and wetting

our in-house capability for wettability measurements

When a coating won’t level, an adhesive won’t bond, or a spray droplet won’t spread, the root cause is often the same: the surface–liquid interaction isn’t what you think it is. Contact angle goniometry is one of the most direct ways to quantify that interaction, and it’s a cornerstone technique for estimating surface energy and comparing wettability across materials, treatments, and lots.

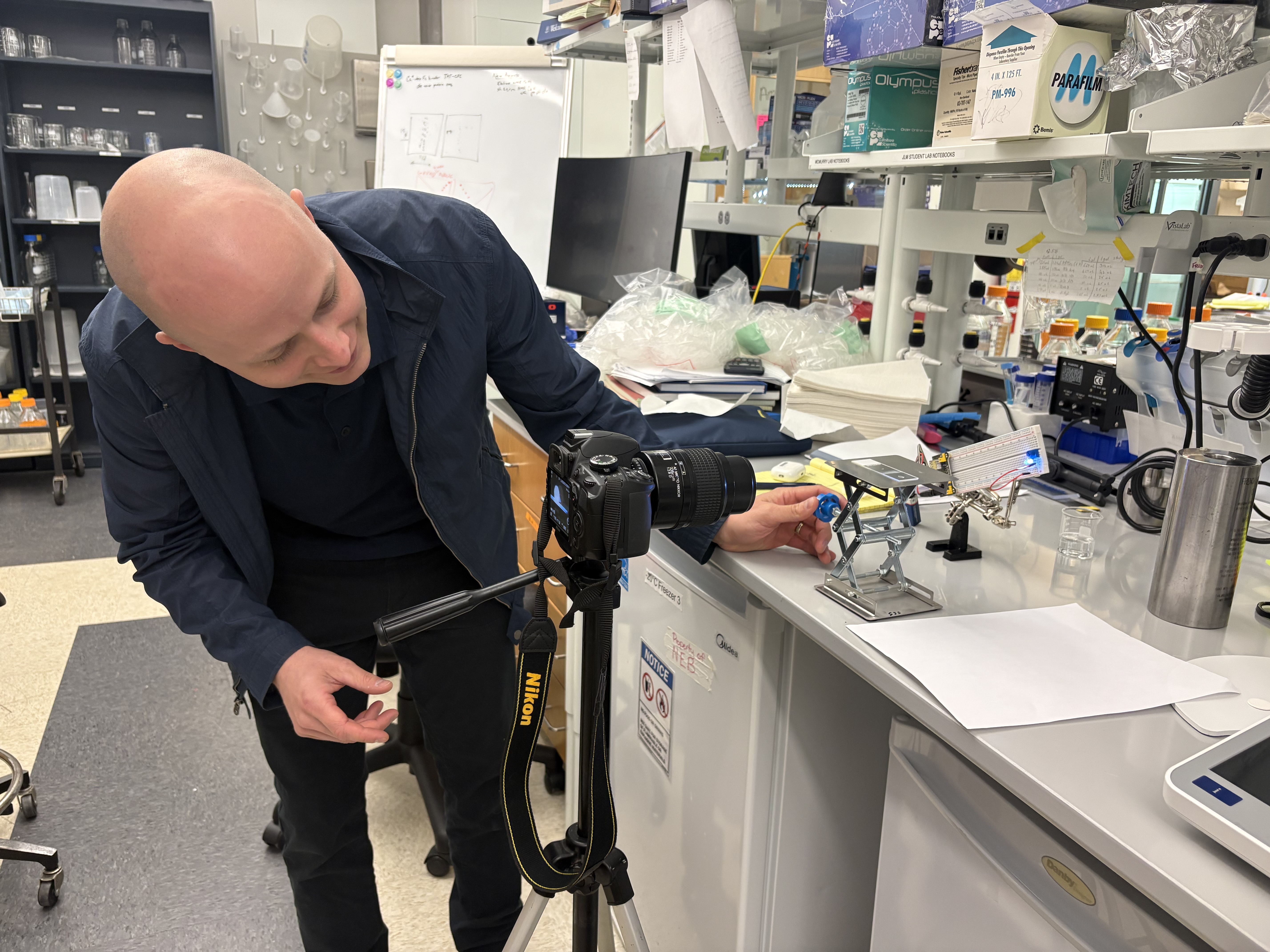

We built a custom contact angle goniometer in-house to support surface-energy work with the repeatability and documentation needed for QC and product-development decisions. This post explains what we measure, how we measure it, and what the results can tell you—especially for adhesives, surface coatings, and agrochemical formulation spreadability.

What contact angle actually measures

A contact angle is the angle a liquid droplet makes at the solid surface at the three-phase boundary (solid–liquid–vapor). Low angles indicate the liquid spreads (good wetting); high angles indicate the liquid beads up (poor wetting). Because the contact angle depends on both the liquid properties and the surface properties, it becomes a practical probe of surface condition.

At equilibrium, contact angle connects to interfacial tensions via Young’s equation:

\[ \gamma_{SV} = \gamma_{SL} + \gamma_{LV}\cos(\theta) \]

Here \( \gamma_{SV} \) is the solid–vapor surface energy, \( \gamma_{SL} \) is the solid–liquid interfacial energy, and \( \gamma_{LV} \) is the liquid surface tension. In real materials and real workflows, “equilibrium” is not always reached, which is why time dependence and advancing/receding behavior often matter as much as a single number.

Why we built a custom goniometer

Commercial goniometers can be excellent. We built our own because we wanted tighter control over the things that drive measurement quality and interpretability:

- Imaging and lighting tuned for challenging samples (matte coatings, textured substrates, thin films, slightly translucent materials)

- Repeatable droplet dispensing (volume control, placement, timing, and minimized operator-to-operator variability)

- A transparent analysis workflow we can validate, audit, and refine (calibration routines, data formats, and repeatability checks)

In short: we wanted an instrument and method that produce contact angles you can trust, not just pictures that look good.

What we report (and why it’s useful)

Depending on the application, we typically report:

- Static contact angle \( \theta \) (left/right and mean)

- Time-resolved contact angle vs. time (useful for absorption, swelling, surfactant migration, or evaporation effects)

- Advancing and receding contact angles (useful for hysteresis, roughness, heterogeneity, and contamination sensitivity)

- Estimated surface energy using multi-liquid models (commonly Owens–Wendt), including polar and dispersive components

These outputs support practical decisions like process control after plasma/corona treatment, incoming material qualification, coating line troubleshooting, and formulation screening for wetting/spread.

How we measure contact angle: a practical method overview

A robust contact angle result comes from controlling mechanics and timing as much as it comes from math. Our measurement workflow emphasizes repeatability and traceability.

1) Sample handling and preparation

Surface measurements are extremely sensitive to handling. We document the sample identity, orientation, cleaning/treatment history, and time since treatment. For treated plastics (e.g., corona or plasma), the time between treatment and measurement can materially affect results due to surface rearrangement.

We also note surface morphology (smooth vs. rough), because roughness can change the apparent contact angle and introduce hysteresis even on chemically uniform surfaces.

2) Instrument setup and calibration

At the start of a run, we verify:

- Optical calibration (pixel-to-length scale using a calibrated artifact)

- Stage level and baseline alignment (tilt shows up as left/right angle bias)

- Lighting stability and edge contrast (consistent droplet silhouette is key)

For routine QC work, we can include a reference check using known surfaces (e.g., clean glass and a low-energy polymer) to confirm the system is behaving as expected.

3) Droplet deposition and timing

We dispense controlled microliter-scale droplets and capture images at defined time points. Timing is not a convenience detail: many systems evolve quickly due to evaporation, absorption, or surfactant effects.

For surfaces or liquids that change rapidly, we prefer to capture a time series so you can see whether the angle stabilizes, drifts, or collapses.

4) Image analysis (from silhouette to angle)

The contact angle is extracted by fitting the droplet profile near the contact line and computing the tangent angle where the fitted profile meets the baseline. We report both left and right angles to expose asymmetry caused by tilt, surface gradients, or droplet placement issues.

When a surface is heterogeneous or textured, left/right differences and increased scatter often carry as much diagnostic value as the mean.

From contact angle to surface energy (Owens–Wendt)

To estimate a solid’s surface energy, we measure contact angles using at least two probe liquids with known polar/dispersive components. A common approach is Owens–Wendt, which splits surface energy into dispersive and polar contributions:

\[ \gamma_S = \gamma_S^d + \gamma_S^p \]

and uses:

\[ \gamma_L(1+\cos\theta)=2\left(\sqrt{\gamma_S^d\gamma_L^d}+\sqrt{\gamma_S^p\gamma_L^p}\right) \]

With two (or more) liquids, we solve for \( \gamma_S^d \) and \( \gamma_S^p \), then report total \( \gamma_S \). Using three liquids can improve robustness and help flag inconsistencies from non-ideal behavior.

A key point for decision-making: surface energy estimates are only as good as the underlying contact angles. A few degrees of bias can shift \( \gamma_S \) by several \( \text{mN/m} \), especially for mid-wetting systems.

Application 1: adhesives and surface coatings

For bonding and coating, contact angles and surface energy help answer questions like:

- Did surface treatment increase polar character (often correlated with improved adhesion)?

- Is a surface contaminated (silicones, mold release, oils) even when it “looks clean”?

- Is a coating defect caused by low surface energy, excessive roughness, or inconsistent treatment?

In practice, a treatment that significantly lowers water contact angle while changing a nonpolar probe liquid angle less dramatically often indicates increased polar functionality at the surface—exactly what many adhesive systems need for stronger interfacial interactions.

Application 2: agrochemical wettability and spreadability

For agrochemical formulations, the focus is often wetting and spreading on hydrophobic biological surfaces, where waxy cuticles and microtexture create high contact angles and strong hysteresis. Goniometry supports formulation development by providing quantitative comparisons across surfactant packages, solvent systems, and adjuvants.

Important nuance: formulated products can be dynamic. Surfactants can migrate to the interface over seconds, changing surface tension and contact angle as the droplet sits. For this reason, time-resolved contact angle (and sometimes advancing/receding measurements) can be more informative than a single snapshot.

A practical screening example: if Formulation A and B start with similar initial angles but A decreases rapidly over ( 10 )–( 60 ) seconds while B remains high, A may deliver better real-world spreading—assuming evaporation and absorption effects are understood and controlled for the specific substrate.

What can bias results (and how we control it)

Contact angle is sensitive by nature. Common issues we watch for include:

- Surface tilt (creates systematic left/right differences)

- Inconsistent droplet volume or dispense rate

- Evaporation (especially small droplets in warm/dry air)

- Porous/absorbing substrates (angle may reflect wicking, not interfacial wetting)

- Roughness and heterogeneity (increases hysteresis and scatter)

- Contamination from handling (fingerprints and trace surfactants can dominate)

We design runs to make these effects visible in the data (left/right reporting, time series, replicate spots), not hidden behind a single averaged number.

What you receive from us

A typical deliverable package can include:

- Test conditions and sample history as provided (substrate, treatment, time since treatment)

- Probe liquids used, droplet volume, timing, and number of replicates

- Contact angles (left/right/mean) and variability across spots

- Time-resolved curves when relevant

- Surface energy results (total, polar, dispersive) when multi-liquid testing is requested

- Representative images for documentation and troubleshooting

If your goal is QC, we can help define acceptance criteria from baseline data (e.g., control charts or practical thresholds tied to pass/fail coating or bonding performance).

When contact angle is the right tool (and when it isn’t)

Contact angle goniometry is ideal for fast comparative assessments, treatment verification, contamination screening, and surface-energy estimation. It’s less straightforward when surfaces are extremely rough, porous, or chemically unstable under the droplet, or when the formulation changes rapidly during measurement.

In those cases, we often recommend adding complementary data (e.g., surface tension of the liquid, microscopy for roughness/texture, or other surface characterization) so the story is consistent and actionable.